Product Systems

High-Performance Coating Systems

Robust, durable, and adaptable: Our construction chemical coatings provide lasting protection against chemical, thermal, and mechanical stresses – in new construction, renovation, and under extreme industrial conditions.

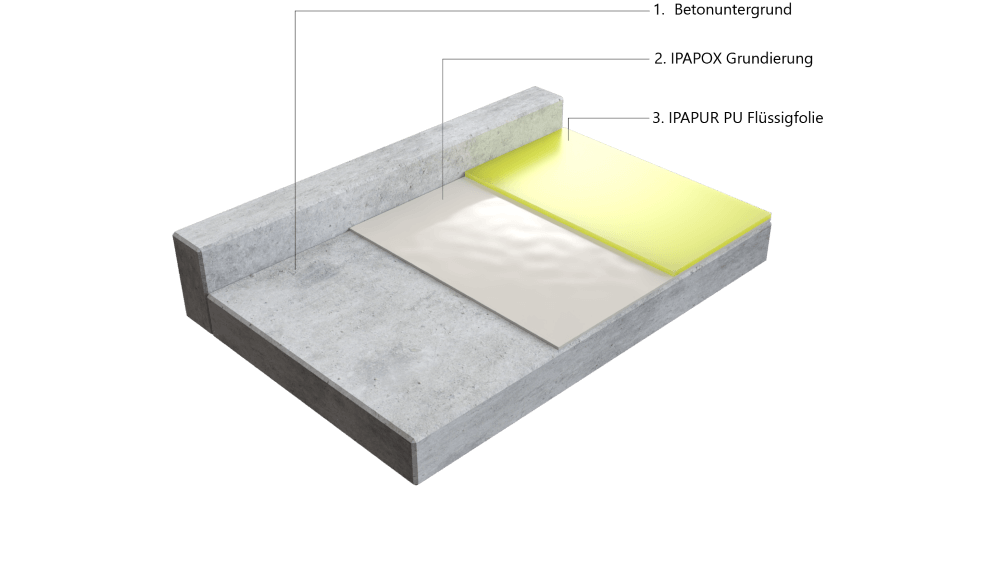

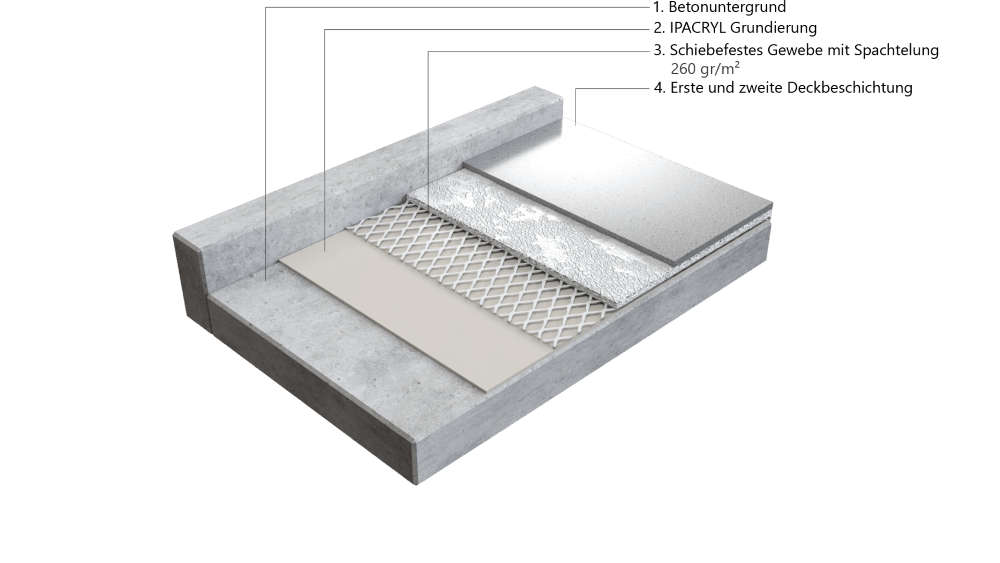

Polyurethane Coatings

High-Performance Systems for Durable Surfaces

Our polyurethane coatings offer reliable protection and high durability for a wide range of indoor and outdoor applications. These 2-component, solvent-free systems feature elasticity, crack bridging, and weather resistance.

Areas of Application

Ideal for the renovation of floors, balconies, containment areas, and parking garages.

Advantages

These coating systems combine functionality, durability, and environmental compatibility – for permanently protected surfaces.

Products

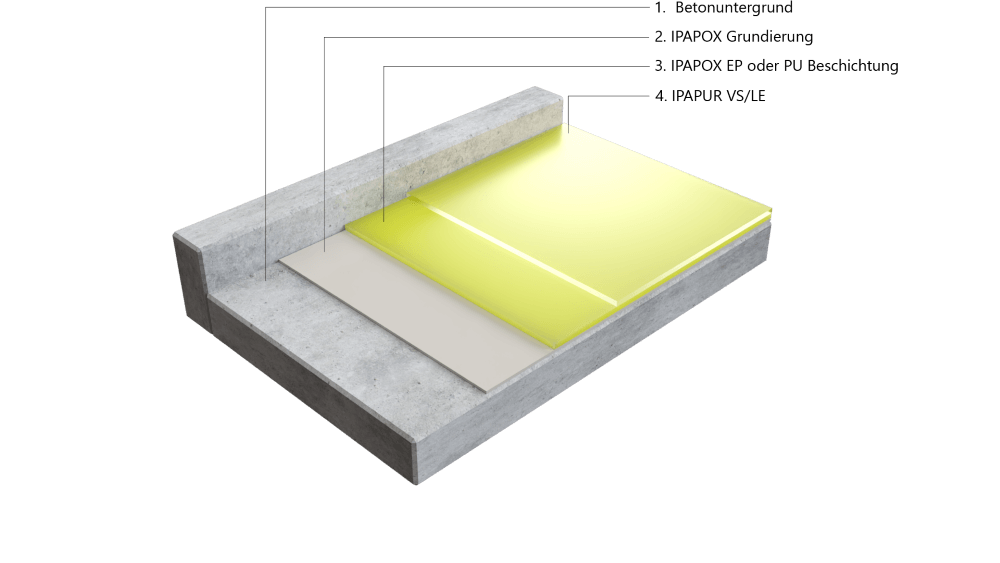

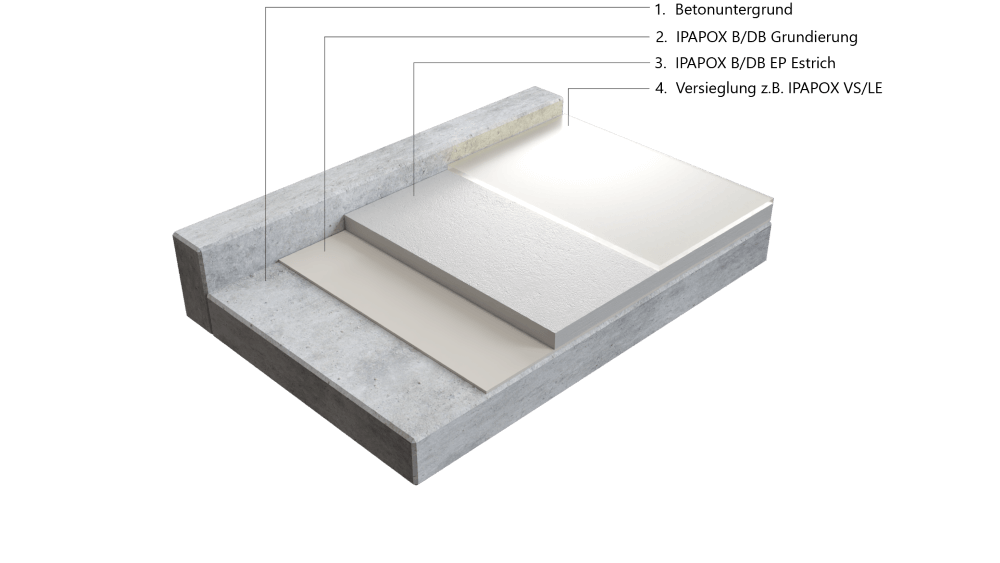

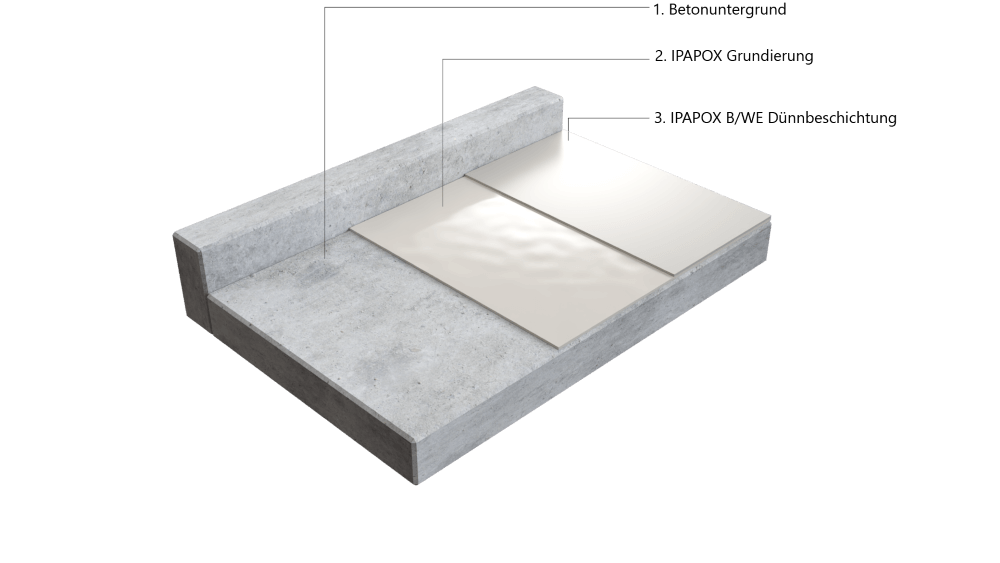

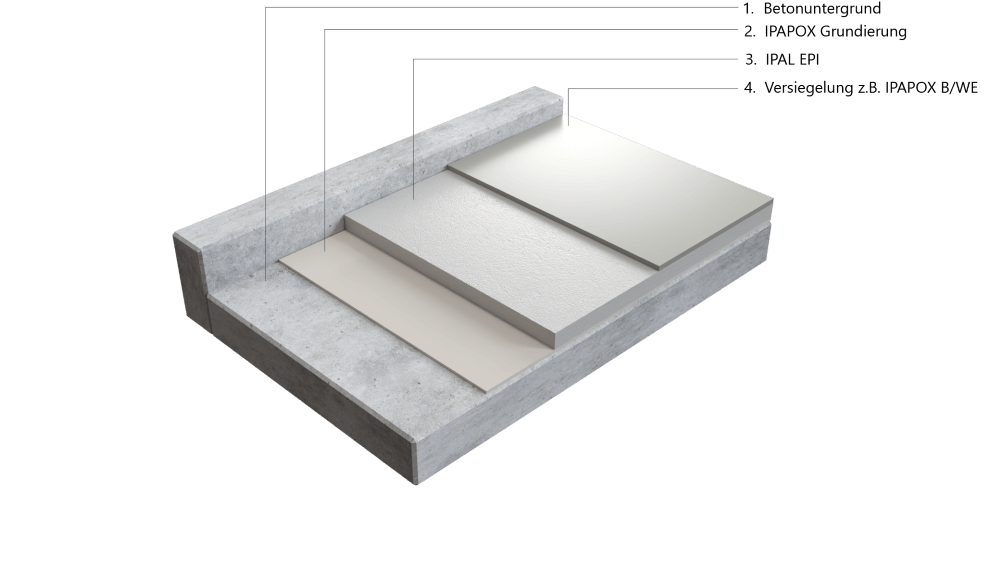

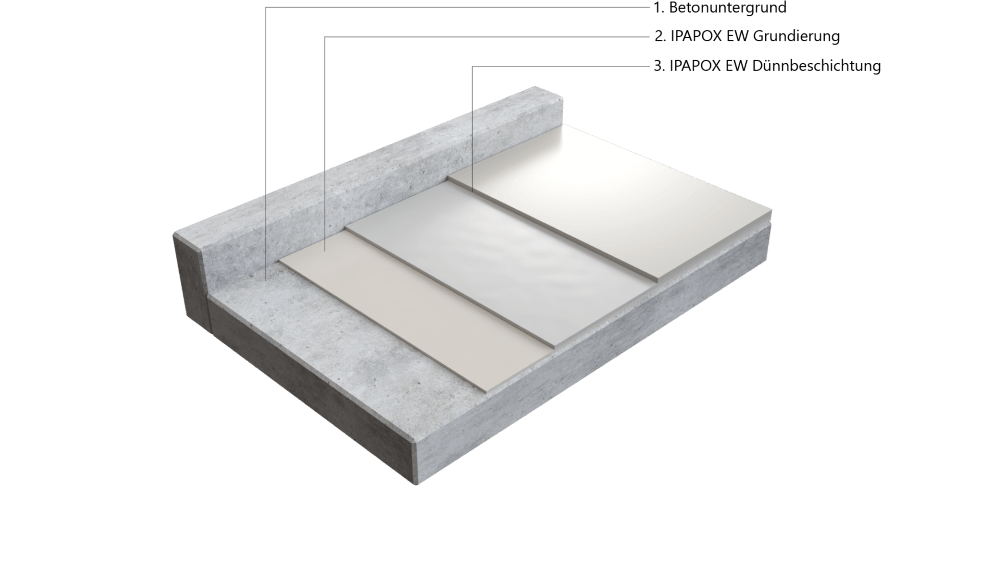

Epoxy Resins

High-Performance Coatings for Maximum Durability

Our epoxy resin systems offer maximum resistance, chemical resistance, and versatility. They are ideally suited for industrial applications on concrete, steel, and mineral substrates – whether as a primer, self-leveling coating, or high-strength mortar.

Areas of Application

For heavy-duty industrial floors, parking garages, balconies, and tunnels.

Advantages

Maximum resistance, customized solutions for every requirement, and permanently durable surfaces for industry, infrastructure, and commercial sectors.

Products

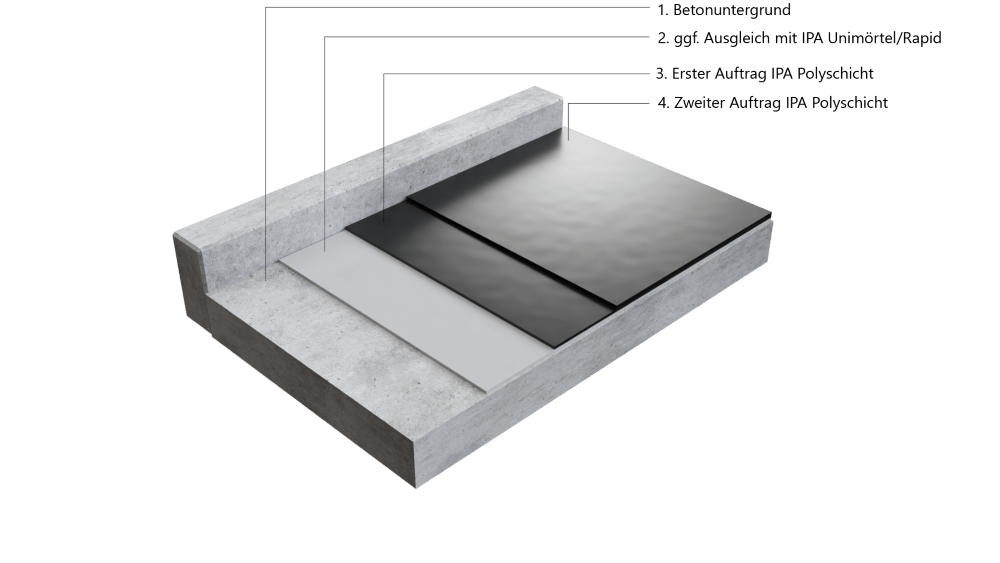

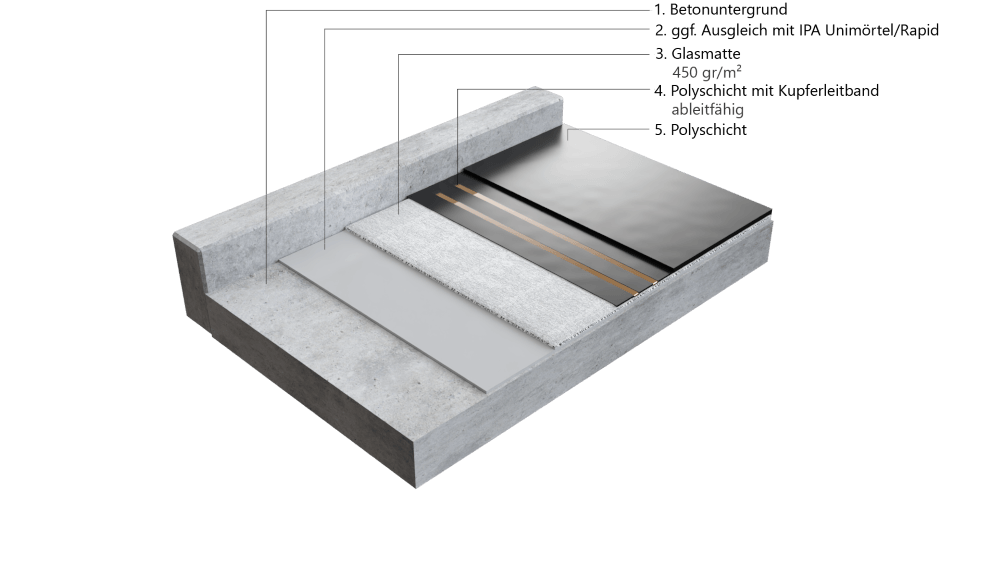

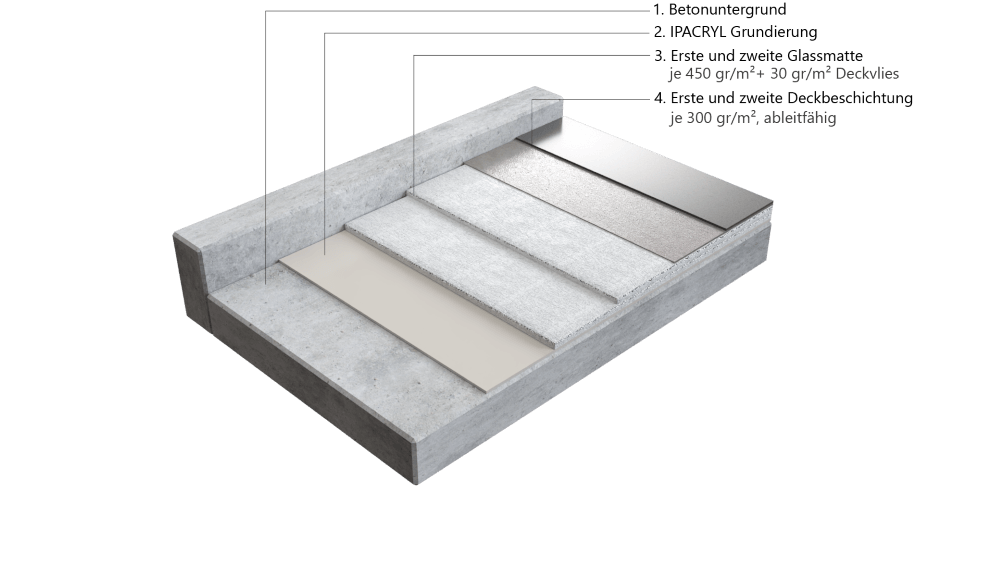

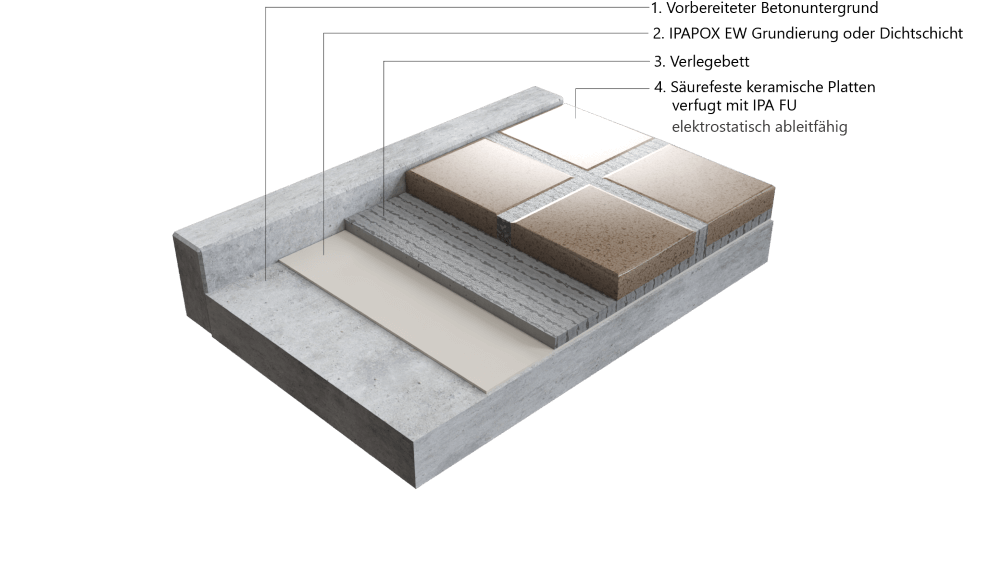

Polymer Silicates

Highly Resistant Coating Systems for Extreme Requirements

Our polymer silicate products offer outstanding chemical, thermal, and mechanical resistance – ideal for use in areas with aggressive media, high humidity, and biogenic sulfuric acid exposure. The systems are electrostatically dissipative, water vapor permeable, and fully cure even underwater.

Areas of Application

Sewer construction, wastewater treatment plants, containment sumps, and biogas plants.

Advantages

Reliable sealing even under extreme conditions, fast processing with shorter construction phases even for small teams, maximum safety with water-hazardous substances – for permanent solutions in environmental and plant engineering.

Products

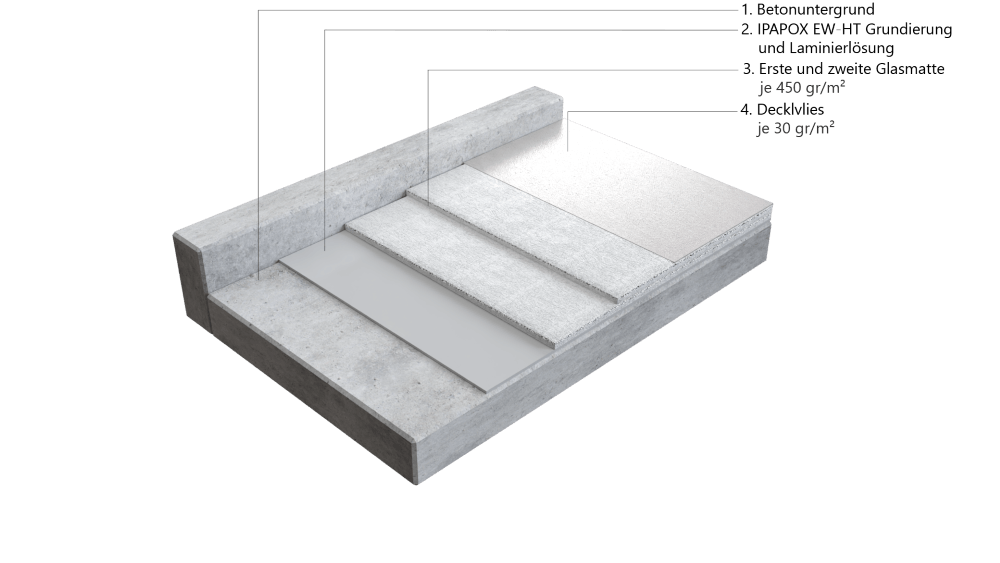

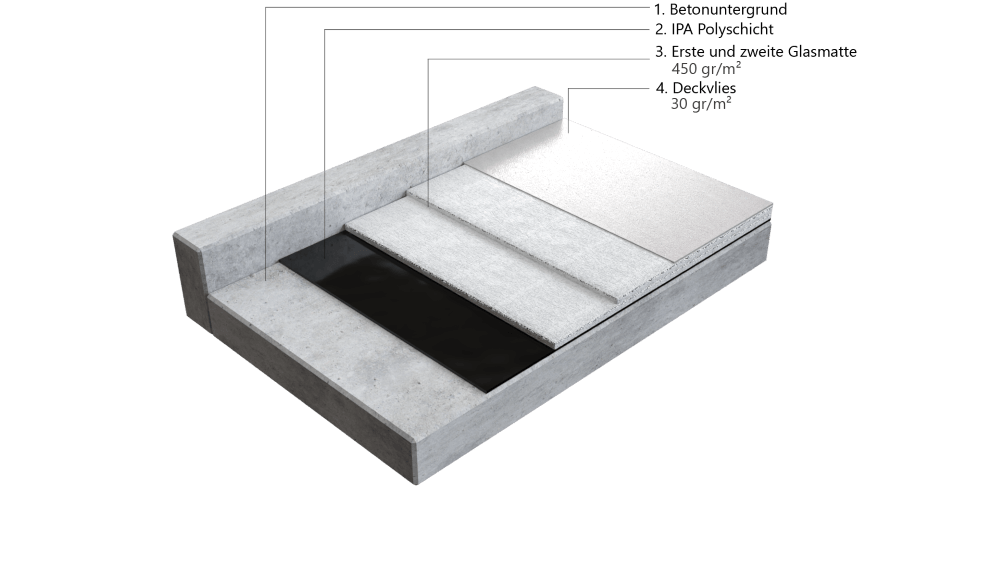

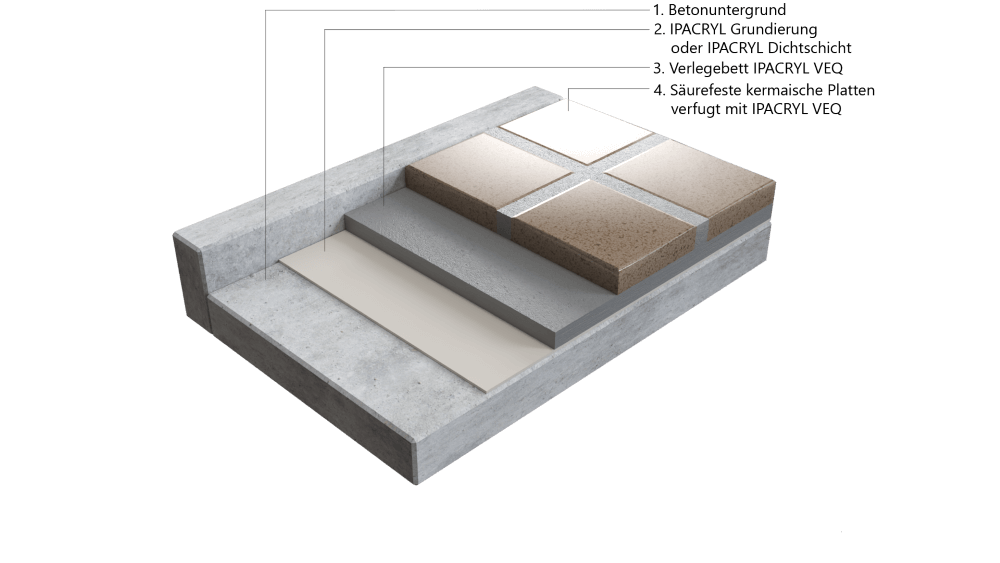

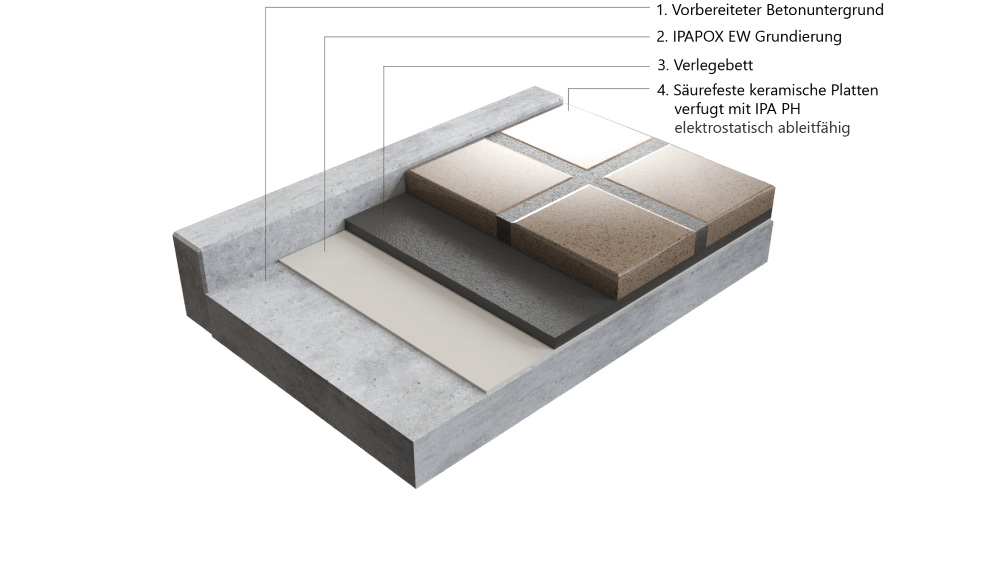

Vinyl Ester Resins

Developed for Extreme Chemical Loads

Our vinyl ester resin systems offer highly effective protection for floors, walls, and joints in demanding industrial environments. They are extremely resistant to aggressive chemicals, oxidizing media, as well as mechanical and thermal stress – ideal for electroplating plants, pickling plants, and HBV facilities.

Areas of Application

Electroplating, Pickling Plants, HBV Facilities

Advantages

Maximum chemical resistance, conductive, versatile, and durable – specially developed for the toughest industrial applications.

Products

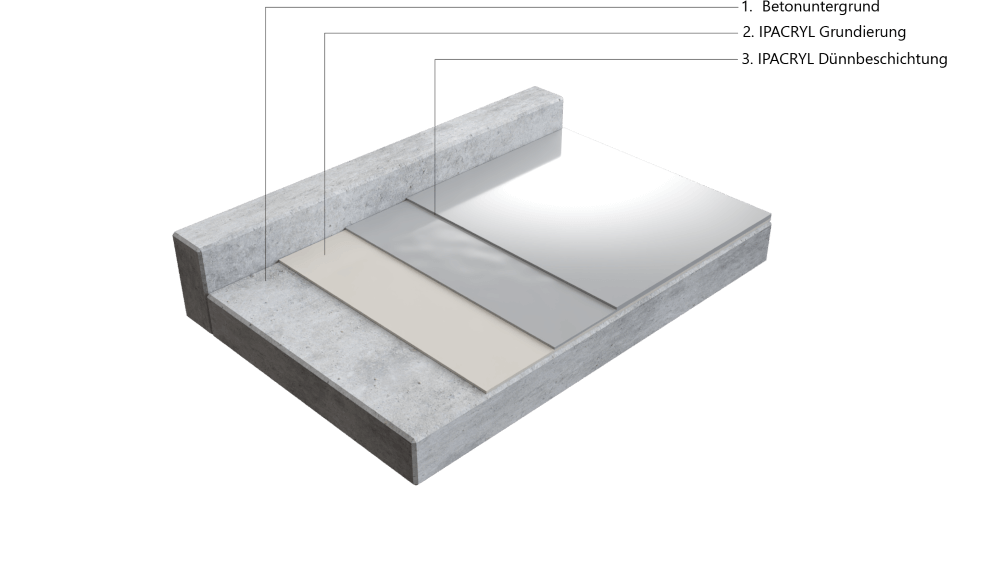

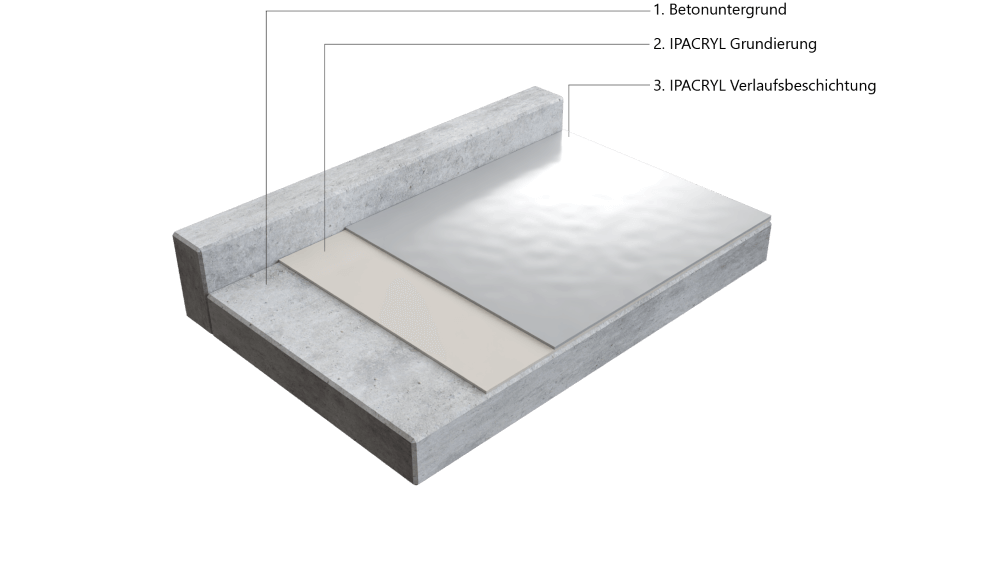

IPACRYL Self-Leveling Coating

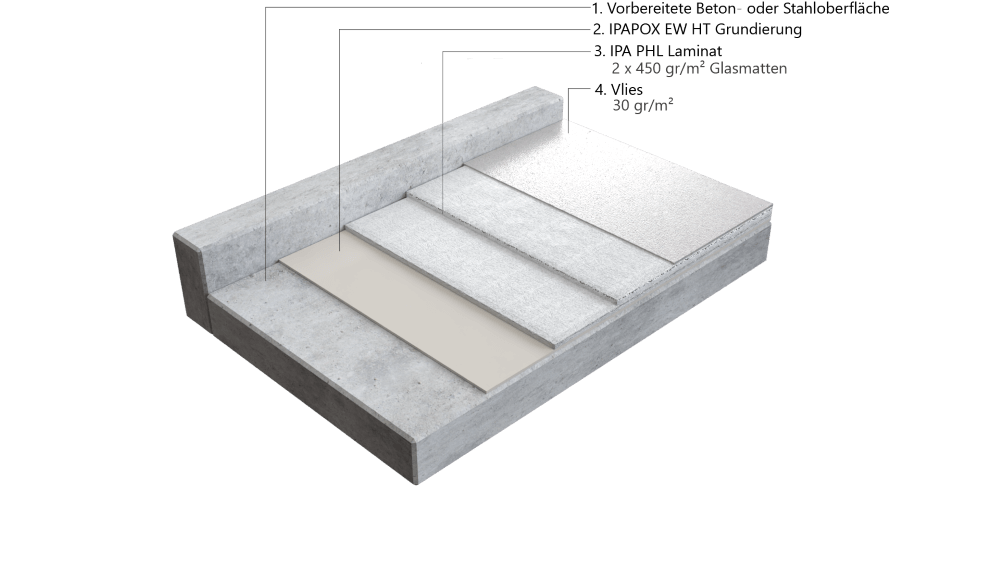

Phenolic Resins

For Highest Chemical and Thermal Loads

Phenolic resin systems are the first choice for use under extremely aggressive conditions. They feature exceptional resistance to strong acids, solvents, and chlorinated hydrocarbons – ideal for industrial applications with the highest demands.

Areas of Application

For highest chemical loads, e.g., methylene chloride.

Advantages

Maximum impermeability, highest chemical resistance, electrical conductivity – for permanent protection under the most extreme operating conditions.

Products

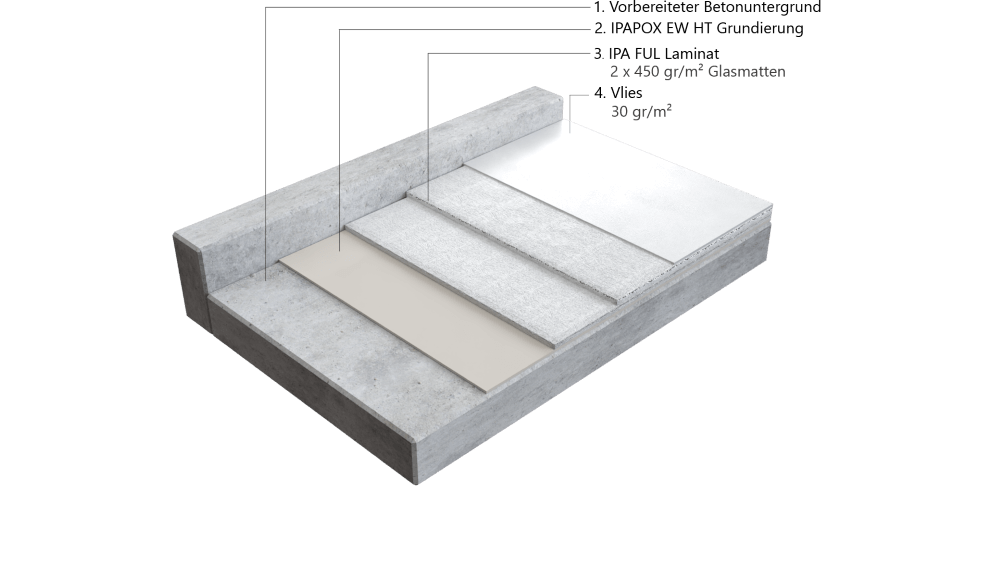

Furan Resins

For Extreme Chemical and Thermal Requirements

Furan resin systems offer reliable protection under the highest chemical loads and extreme temperatures. They are ideal for industrial applications where conventional coatings fail, e.g., in chemical plants, pickling plants, or high-temperature areas.

Areas of Application

Thermally chemically heavily stressed surfaces up to 300 °C

Advantages

Excellent chemical resistance, high temperature resistance, electrical conductivity – furan resins are the robust solution for extreme conditions.

Products

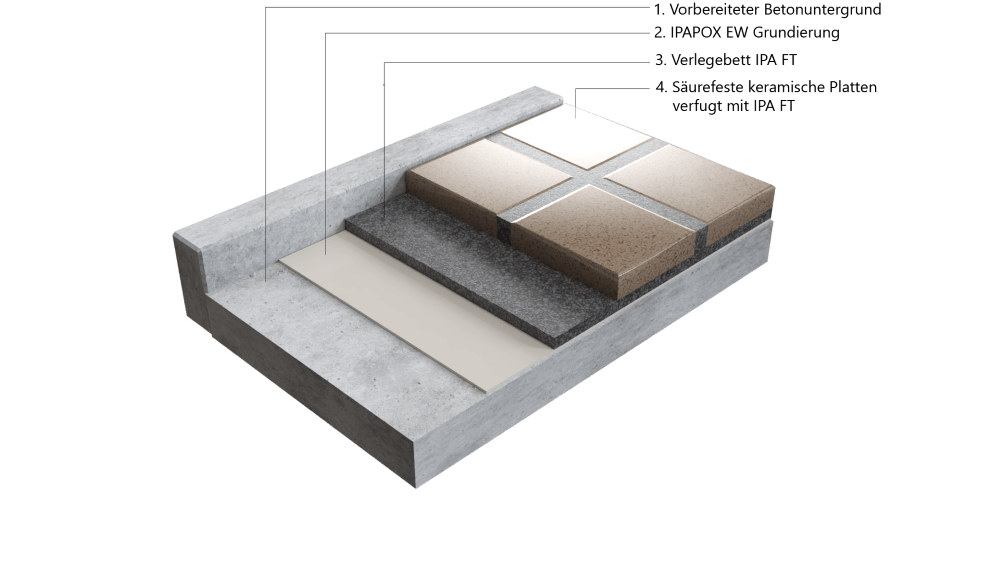

IPA FT

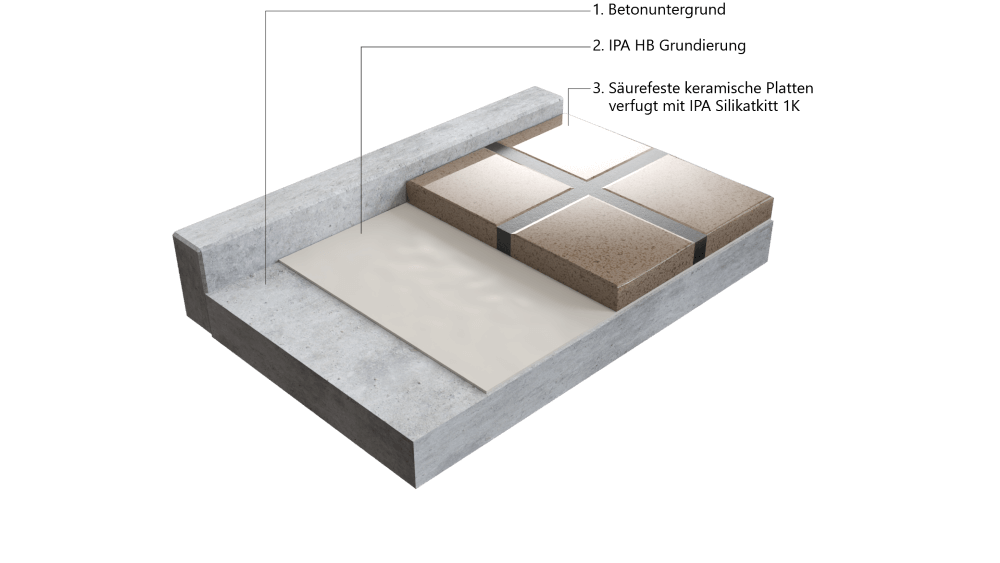

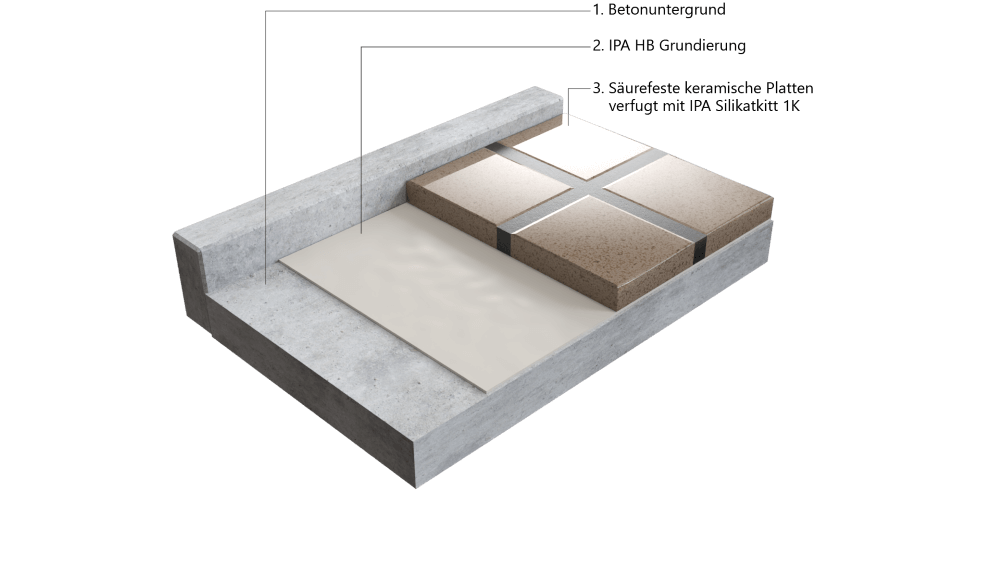

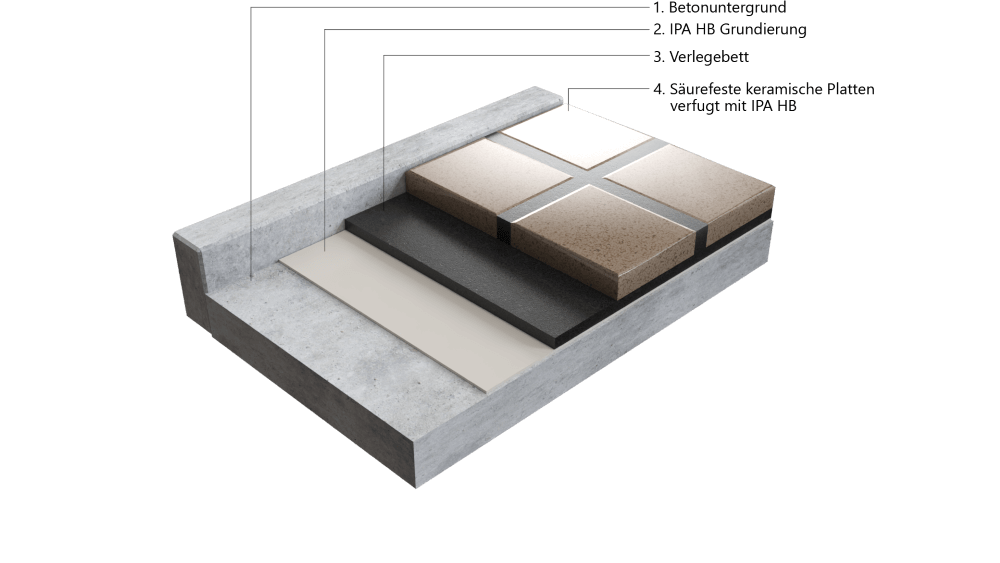

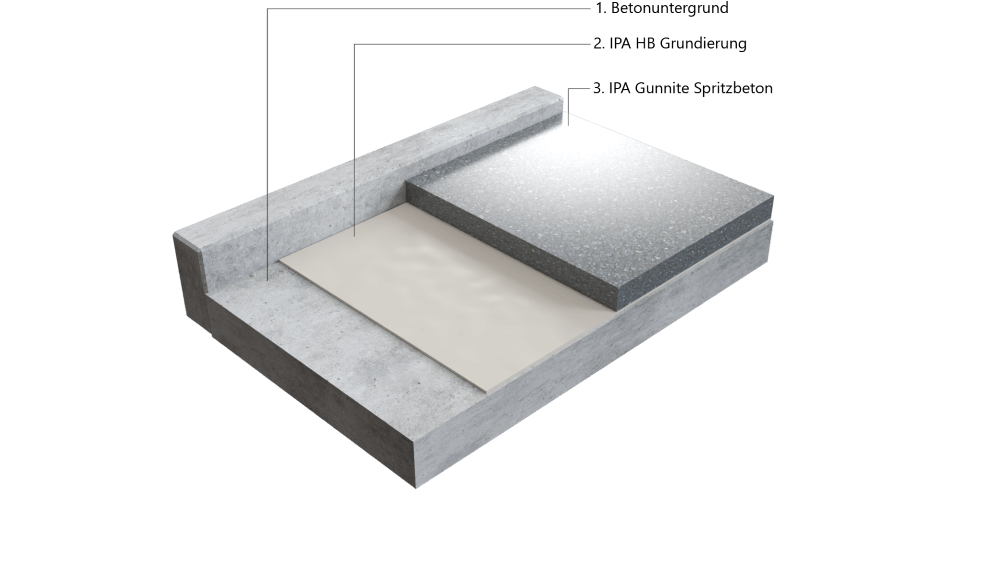

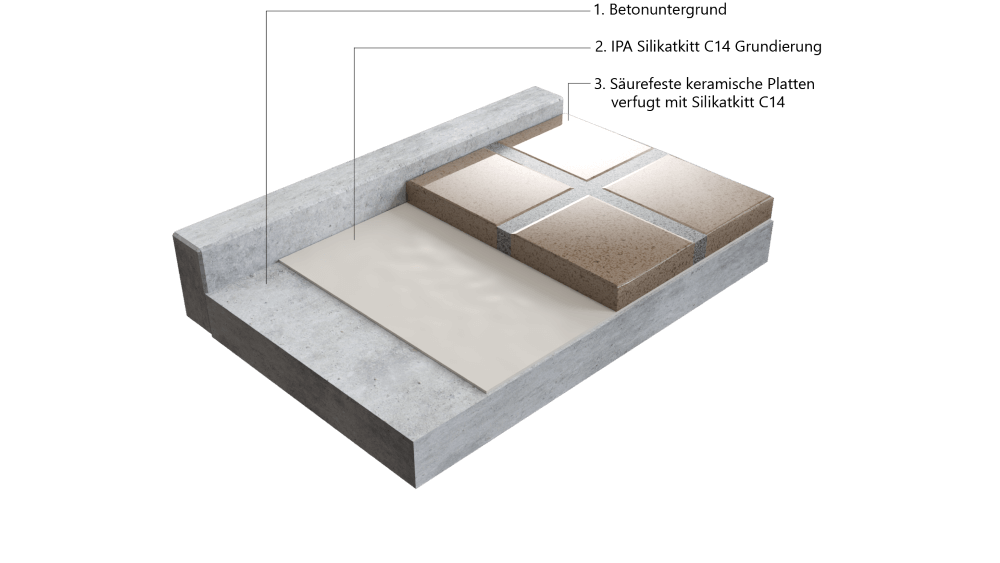

Silicate Putties

Acid-Resistant Mortars for High-Temperature and Special Applications

Water glass-based silicate putties are halogen-free, mineral systems for the reliable installation of acid- and temperature-resistant linings. They are particularly suitable for tank construction, chimney construction, and industrial brick linings.

Areas of Application

Chimney Construction, Brick Lining, Corrosion Protection

Advantages

Acid-resistant, halogen-free, temperature-resistant – silicate putties are the first choice for permanently stable, chemically and thermally durable linings in industry and chimney construction.