IPA INJECTION IN BUILDING CONSTRUCTION

Proper crack repair

Proper crack repair is only promising if the causes of the crack formation are known. In addition to planning errors, poor workmanship, improper use, static overload, etc., cracks can also occur due to the building material.

The following are the causes of the crack, among others:

- Poor concrete quality, gravel nests, demixing, work stoppages during the concreting process, etc.

- Improper allocation of reinforcing steel, insufficient component cross-sections

- Changes in length due to thermal stresses from weather influences: solar radiation.

- frost or fire damage

- Mechanical and dynamic overload from settlements, exceeding the payload, traffic, earthquakes, etc.

Cracks should be treated in the following situations:

- indoors with normal humidity> 0.3mm

- outdoors and in rooms with high humidity> 0.2mm

- under water stress and in an aggressive environment> 0.1mm

IPA CRACK TREATMENT SYSTEMS

According to DIN EN 1504-5, repairing cracks can have different objectives. This in turn means that the selection of the injection materials (filling material) must have the highest priority. The following objectives can be achieved by injecting cracks and defects:

Prevent ingress of corrosive media

IPAPUR IF

PUR Injection grout for elastic sealing of cracks in concrete structures

TECHNICAL DATA SHEET IPAPUR IF

IPAPUR IF NV100

PUR Injection grout for elastic sealing of cracks in concrete structures

TECHNICAL DATA SHEET IPAPUR IF NV100

IPAPUR IS

Injection resin for bonding cracks and cavities in concrete and masonry.

IPANEX VDMS Injektionsleim

Cement-bound, mineral injection material, sealing mortar suspension

TECHNICAL DATA SHEET IPANEX VDMS INJEKTIONSLEIM

IPA VM6 (Microfeinstzementsuspension)

IPA VM 6 is a factory-mixed, cement-bound injection material based on ultra-fine cements according.

TECHNICAL DATA SHEET IPA VM6

IPACRYL Gel Konzentrat

Low-viscosity, modified 2-component acrylic resin gel with excellent water-binding properties, for sealing water-bearing cracks, gaps and structural joints Technical data sheet IPACRYL GEL KONZENTRAT

IPAPUR VM 1K

1 comp. PU injection foam especially for sealing water-bearing cracks in structural and civil engineering, eg water ingress, in civil engineering, for displacing water in water-bearing cracks and cavities.

TECHNICAL DATA SHEET IPA VM 1K

IPAPUR VM

Low viscose, elastic, foaming Pu Injection Resin Used To Seal Water-Bearing moving cracks and joints

TECHNICAL DATA SHEET IPA VM

IPAPUR VP

Low viscose, elastic, foaming Pu Injection Resin Used To Seal Water-Bearing moving cracks and joints

TECHNICAL DATA SHEET IPA VP

IPACRYL Gel Konzentrat

Low-viscosity, modified 2-component acrylic resin gel with excellent water-binding properties, for sealing water-bearing cracks, gaps and structural joints Technical data sheet IPACRYL GEL KONZENTRAT

IPANOL IH

Injection and Grouting Resin for Gravity-Actuated Crack Bonding and Making Up High-Strength, Impact-Resistant Resin and ECC Mortars.

TECHNICAL DATA SHEET IPANOL IH

IPAPOX IH/E

Very Low-Viscosity Injection Resin Suitable for Grouting and Sealing Hairline Cracks.

TECHNICAL DATA SHEET IPANOL IH/E

IPAPOX IH/R

Low-Viscose Epoxy-Injection and mortar resin with very fast reaction time

TECHNICAL DATA SHEET IPANOL IH/R

IPAPOX IH/L

Coating Resin Used to Make Filled Synthetic-Resin Thick-Layer Coats and Screeds with extra long potlife for hot countries

TECHNICAL DATA SHEET IPANOL IH/L

IPAPUR IS

Injection resin for bonding cracks and cavities in concrete and masonry.

IPA Injektionsmörtel VMQ

Highly sulphate resistant, swellable mineral grout with water-repellent properties

IPA Injektionsmörtel THS

Mineral grout, highly sulphate resistant, for masonry containing gypsum

IPA Injektionsmörtel VM3

Cement-bound injection material for crack injection from 3.0 mm crack width

IPANEX VDMS Injektionsleim

Cement-bound, mineral injection material, sealing mortar suspension

TECHNICAL DATA SHEET IPANEX VDMS INJEKTIONSLEIM

IPA VM6 (Microfeinstzementsuspension)

IPA VM 6 is a factory-mixed, cement-bound injection material based on ultra-fine cements according.

TECHNICAL DATA SHEET IPA VM6

IPA PM pulver

IWhite powder for mixing, thin-liquid injection grouts and concrete Avoids segregation and shrinkage of cement mortars, slightly expansive.

TECHNICAL DATA SHEET IPA PM PULVER

IPAPUR IF

PUR Injection grout for elastic sealing of cracks in concrete structures

TECHNICAL DATA SHEET IPAPUR IF

IPAPUR IF NV100

PUR Injection grout for elastic sealing of cracks in concrete structures

TECHNICAL DATA SHEET IPAPUR IF NV100

IPA Injektionsmörtel VMQ

Highly sulphate resistant, swellable mineral grout with water-repellent properties

IPA Injektionsmörtel THS

Mineral grout, highly sulphate resistant, for masonry containing gypsum

IPA Injektionsmörtel VM3

Cement-bound injection material for crack injection from 3.0 mm crack width

IPANEX VDMS Injektionsleim

Cement-bound, mineral injection material, sealing mortar suspension

TECHNICAL DATA SHEET IPANEX VDMS INJEKTIONSLEIM

IPA VM6 (Microfeinstzementsuspension)

IPA VM 6 is a factory-mixed, cement-bound injection material based on ultra-fine cements according.

TECHNICAL DATA SHEET IPA VM6

IPA PM pulver

IWhite powder for mixing, thin-liquid injection grouts and concrete Avoids segregation and shrinkage of cement mortars, slightly expansive.

TECHNICAL DATA SHEET IPA PM PULVER

IPAPOX FM/E

Permanently Elastic Injection Resin and Jointing Compound.

TECHNICAL DATA SHEET IPAPOX FM/E

IPA Injektschlauch

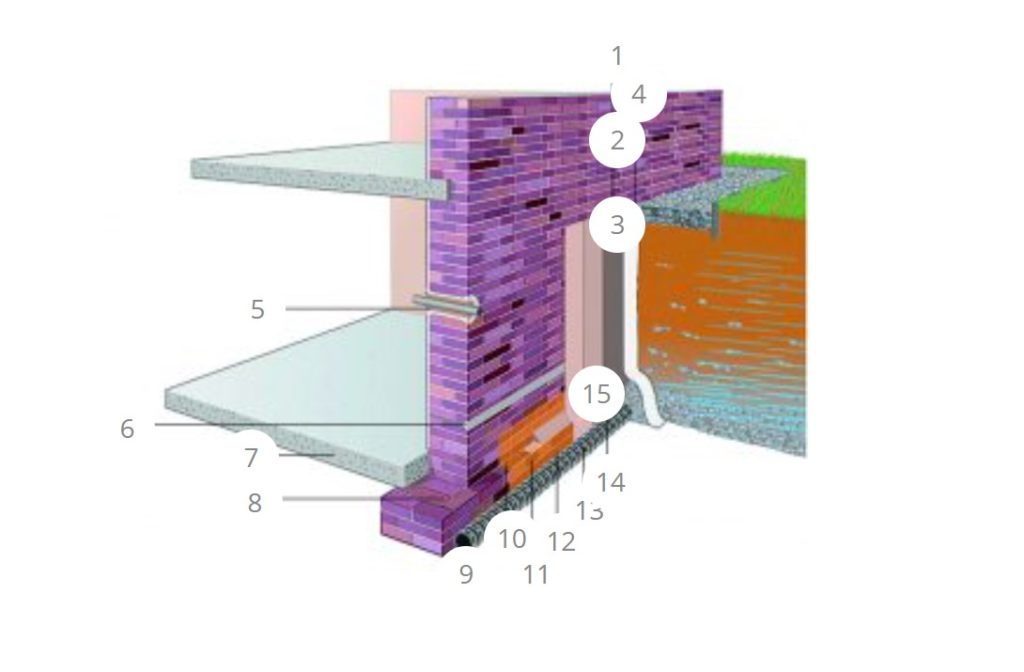

IPA FLOOR INJECTION AND VEIL INJECTION

This type of sealing should always be selected if either the appearance of the building material surface must not be changed or if large amounts of water have infiltrated through the components into the interior of the building during sealing.

The injection curtains can be used as a flat seal or partially for cracks, cavities, connections, penetrations or joints, horizontally or vertically. They serve partly as a completion for the subsequent internal sealing with mineral sealing systems.

Depending on the water load, silicates, cements and moisture-tolerant acrylic resin gels can be used as injection materials. The viscosity must be matched to the building material to be injected.

Likewise, the proof of environmental compatibility must comply with the statutory provisions. In the case of surface injections, in the case of punctiform injections, individual drilling channels may be produced.

Drill hole grid and depth are to be arranged depending on the material distribution and component thickness. If necessary e.g. B. in the case of heavy water leakage, poor joint network or fissured surface, a pre-insulation should be carried out with mortar if necessary. Drilling, percussion or special packers can be installed in the drilling channels.

Injection Resin like a Gel with adjustable reaction time for waterstopping.

2-com. Injection-material to produce soil and masonry-consolidations and to produce curtaininjections into construction ground